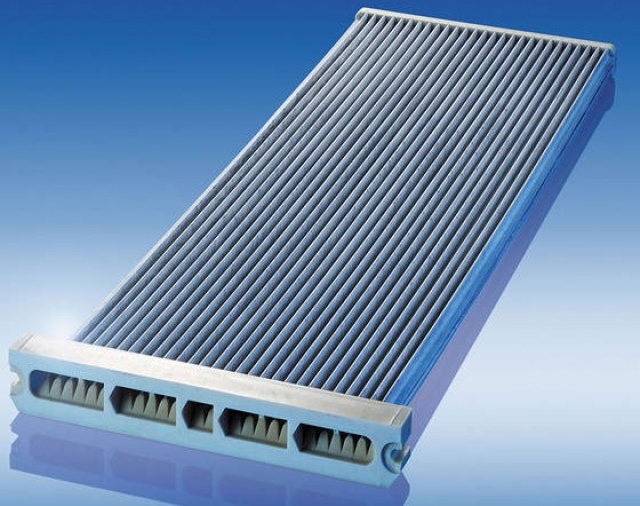

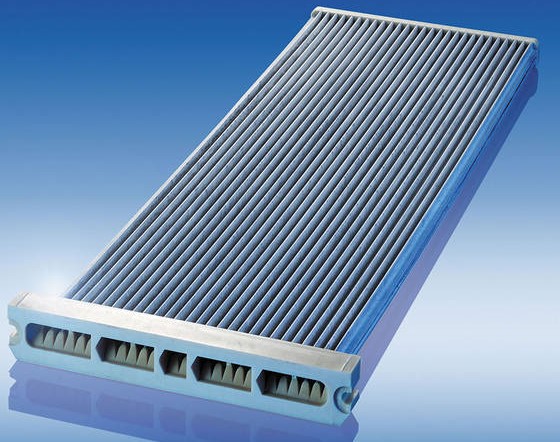

Sintered filters

Sintered filters has no ordinary textile filters. Instead, the filtration happens through sintered plastic elements which are also known as sintered elements. The material used in the sintered elements consists of a base made of polyethylene (PE) and a coating made of polytetrafluoroethylene (PTFE). The combination of the geometrical design and its hard material gives the sintered element unique properties which result in many benefits compared to conventional filtration. The sintered elements are developed by the German filtering company Herding Gmbh Filtertechnik. They have a global patent on the filtering material and the production is performed under strict surveillance at Herding’s own manufacturing facilities in Amberg, Germany.

Benefits compared to filters using textile materials:

Benefits compared to filters using textile materials:

- Extremely low dust emissions, approximately 0.1 mg/m3.

- Up to a 10-year lifespan, even for very abrasive dust.

- The material is inelastic and does not move.

- Compact filters due to the geometry of the sinter elements.

- Can easily be cleaned online, with low compressed air consumption.

- The filtering material does not contain any fibers, which is ideal for re-use of the dust.

- Constant differential pressure and emission levels.

- Robust and stable material which gives good mechanical abrasion resistance.

- Minimal maintenance.

Please contact us for more information. You can also visit: www.herding.de

a79a56bb13

Anlage 1

ecp

How to get in touch:

info@ecpairtech.se+46 76 115 20 97

+46 76 115 20 91

Welcome to visit us!

ECP AirTech ABLjudbojsvägen 2

865 51 Ankarsvik

With modern technology we combine environmental responsibility with

economic effectivity.

economic effectivity.